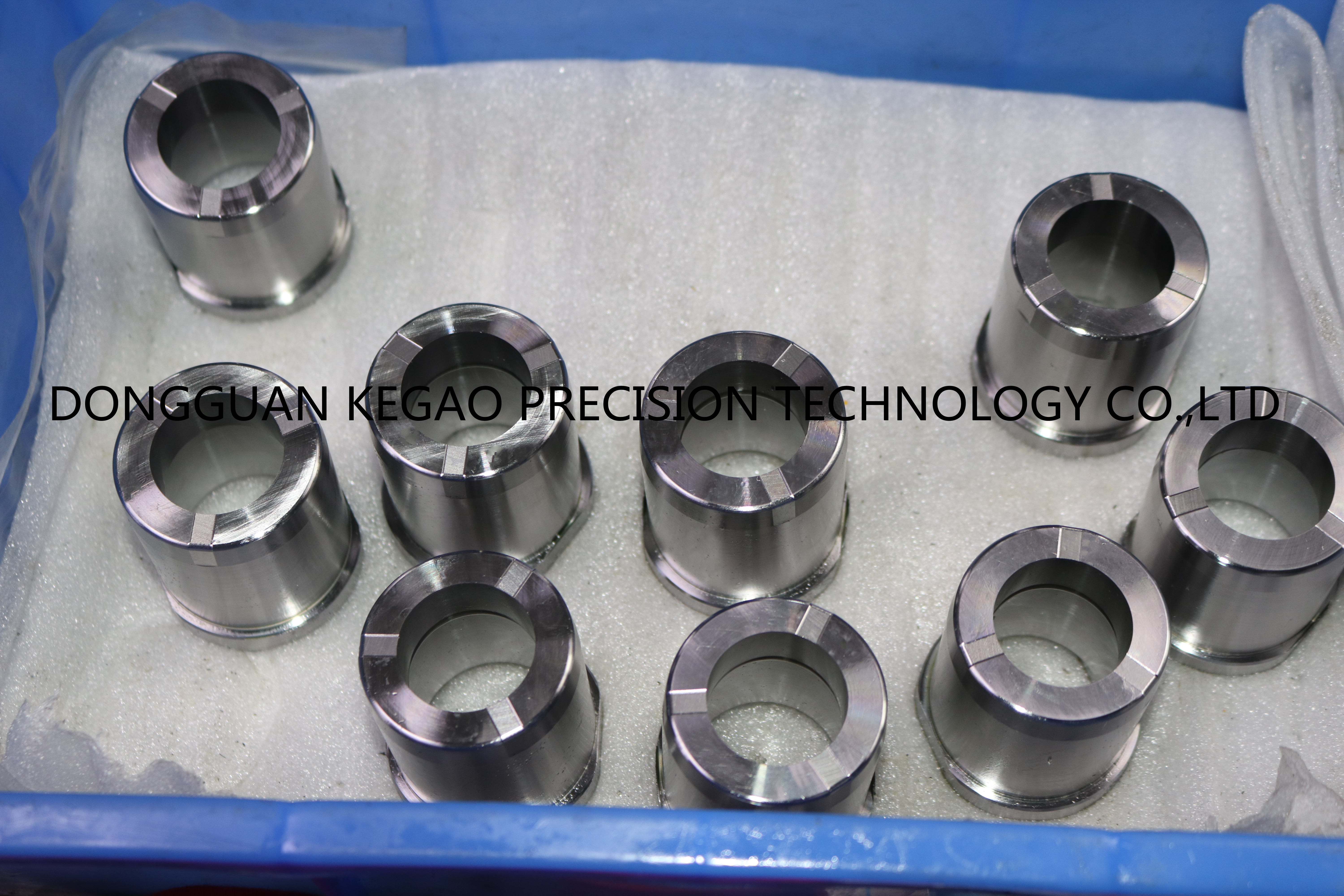

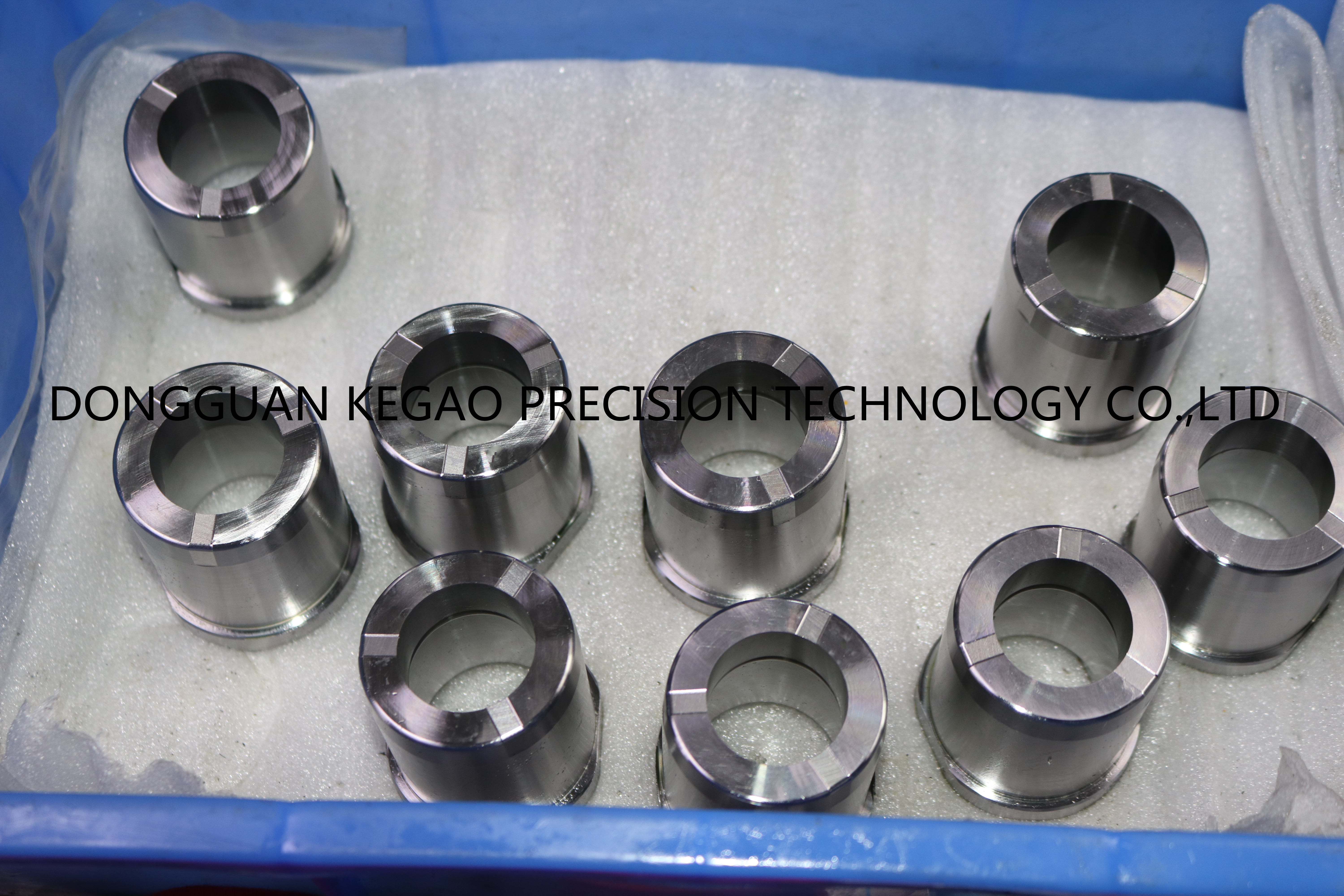

Ejection Side Cavity For Injection Molding Automotive Parts And

SWPH13 Material

Description:

| Parts Name: | Ejection Side Cavity For Injection Molding Automotive Parts And

SWPH13 Material | Hardness: | 46-48 |

| Product size: | Customized/As Per Drawings | Grinding accuracy: | ±0.001mm |

Product material:

| Japan (SKD11.SKD61.SKH51.S45C) | Tolerance: | 0.001mm |

| USA (AISA.D2.H13.P20.M2) | EDM Accuracy: | ±0.003mm |

| Germany (DIN.2379.2363.2344.2347) | Grind Clear Angle Max: | 0.02 |

| ASSAB(Rigor.DIVEAR.Impax.Elmax.VANADIS4.STAVAX) | EDM Angle Max: | 0.02 |

| Process: | CNC→Grinding.... | Grinding Finish Ra: | 0.2 |

| Application: | Ejection Side Cavity For Injection Molding Automotive Parts | EDM Finish Ra: | 0.3 |

| | Wire Cutting Finish Ra: | 0.3-0.4 |

| Processing flow: | Heat treatment →CNC→Grinding→Quality inspection |

Our feature:

1. 100% QC inspection before shipment;

2. Feedback within 24 hours and Good English Communication;

3. Good training export sales can give professional suggestion on

product;

4. Customized making according to your drawing papers;

5. Accept trial order and small order;

6. Accept all payment terms of T/T, L/C, western union,

Paypal,Trade Assurance,etc.;

7. Offer free samples under the condition of freight paid by

customer;

Our Advantages:

Consistent Quality Control:

1.We have very experienced staffs can control the parts to exact

dimensions in the process of production.

2.Our experienced QCs inspect all the parts thoroughly which can

ensure 100% high quality products sent to you .

Excellent customer support:

Before sales service-in sales-after sales service are available,

please feel free to contact us at anytime,we will best service with

you!

Competitive price:

based on reasonable calculation, our price is always competitive

which can support customers at the first round of competition,can

help customers save the inquire time.

Shipping:

DHL, FedEx, UPS, TNT,by Sea .

Inspection Equipments:

CMM, Altimeter, Calipers, Micrometer, 2.5D, Projector, Hardness

Tester etc.

FAQ:

Q1: Where Is Your Factory Located? How Can I Vist There?

A: Our factory is located in NO.27,ShangLang Road,XiaBian

District,Chang'an town, Dongguan China

All our clients from home or abroad are warmly welcomed to visit us

at any time.

Q2: When Can I Get The Quotation Or The Reply On Your Side?

A: The swift response will usually be taken within 4 hours after we

got your inquiry or email.If you are very urgent,please let us know

so that we will regard your inquiry priority

Q5: What Will You Do After Sales?

A: We have after-sales servise, when you received our products,we

will follow up and await your feedback.

Any question related to our products,our experienced engineers are

ready to help.

Further Information

| Testing machine | Digital Height Gauge, caliper, Coordinate measuring machine,

projection machine,roughness tester, hardness tester and so on. |

|

| QC | 1) Technicians self-check in production |

| 2) Engineer spot check in production |

| 3) QC inspects after mass production finished |

| 4) International sales who were trained the technical know-how spot

check before shipping |

| Main Markets | North America, South America, Eastern Europe , West Europe ,

NorcEurope, South Asia, Africa Africa |

|