PD613 Material and Shaft sleeve for Precision Automatic mould parts

Dongguan Kegao Precision Technology Co., Ltd. was found in 2007, is

mainly engaged in the R&D, manufacture, sales and service of

precision mould in one of the precision mould parts manufacturers,

which have been widely applied in many fields, such as precision

medical mould, connector mould,various types of cosmetic mould, PET

preform mould, medical apparatus & instruments, jig, etc. We also

provide many types of precision mould parts, jig parts,

non-standard, standard round parts, as well as machine parts.

Description:

| Parts Name: | PD613 Material and Shaft sleeve for Precision Automatic mould parts | Hardness: | HRC58 |

| Product size: | Customized/As Per Drawings | Grinding accuracy: | ±0.001mm |

Product material:

| Japan (SCM415.SKD61.SKH51.S45C) | Tolerance: | 0.001mm |

| USA (AISA.D2.H13.P20.M2) | EDM Accuracy: | ±0.003mm |

| Germany (DIN.2379.2363.2344.2347) | Grind Clear Angle Max: | 0.02 |

| ASSAB(UNIMAX.DIVEAR.Impax.Elmax.VANADIS4) | EDM Angle Max: | 0.02 |

| Process: | Grinding →CNC | Grinding Finish Ra: | 0.2 |

| Application: | Clamp Nut for Precision Automatic mould parts | EDM Finish Ra: | 0.3 |

| | Wire Cutting Finish Ra: | 0.3-0.4 |

| Processing flow: | Heat treatment →Grinding →CNC→Quality inspection |

Packing:

Outside package: Standard carton box;

Inner package: PE film, PE bag & plastic box;

anti-rust oil.

Delivery Time:

In common 5-15 working days, it depends on the quantity of order

and complexity of drawings

Key Specifications/ Special Features

1. Surface Treatment: We can supply some surface treatments for

you. such as:

Polishing/ Mirror polishing/ PVD coating/ DLC coating and so on, Or

custom is welcomed according to your requirement.

2. Material: There are some material categories available, details

as follows:Stainless steel/ aluminum/ brass/ iron/ zinc/ high speed

steel/ copper, etc.

3. Material or size and others, we will give you OEM service

according to customer requirements

4. Parts Usage: We are a enterprise with mold parts processing ,

since its inception, our parts have been used in many different

industries, such as automotive, electronic equipment, aviation,

medical and so on.

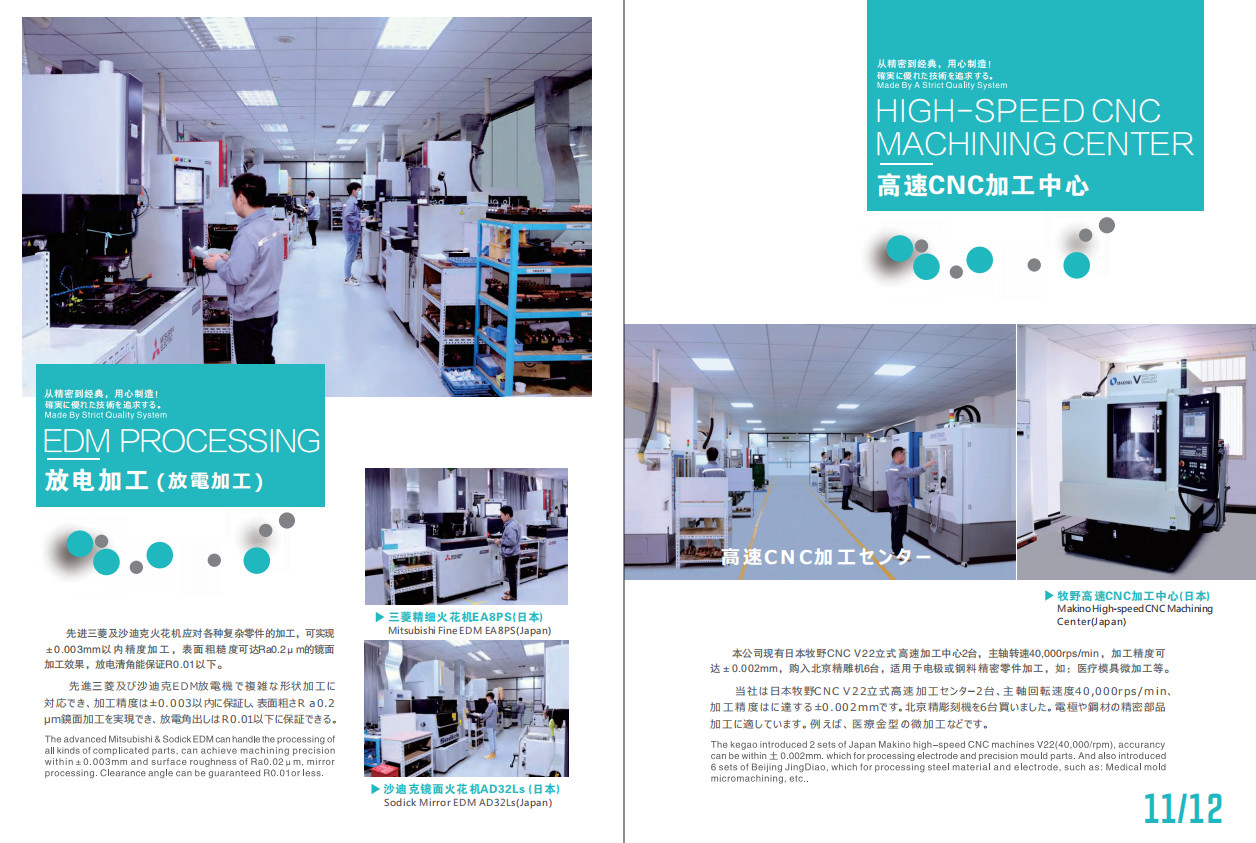

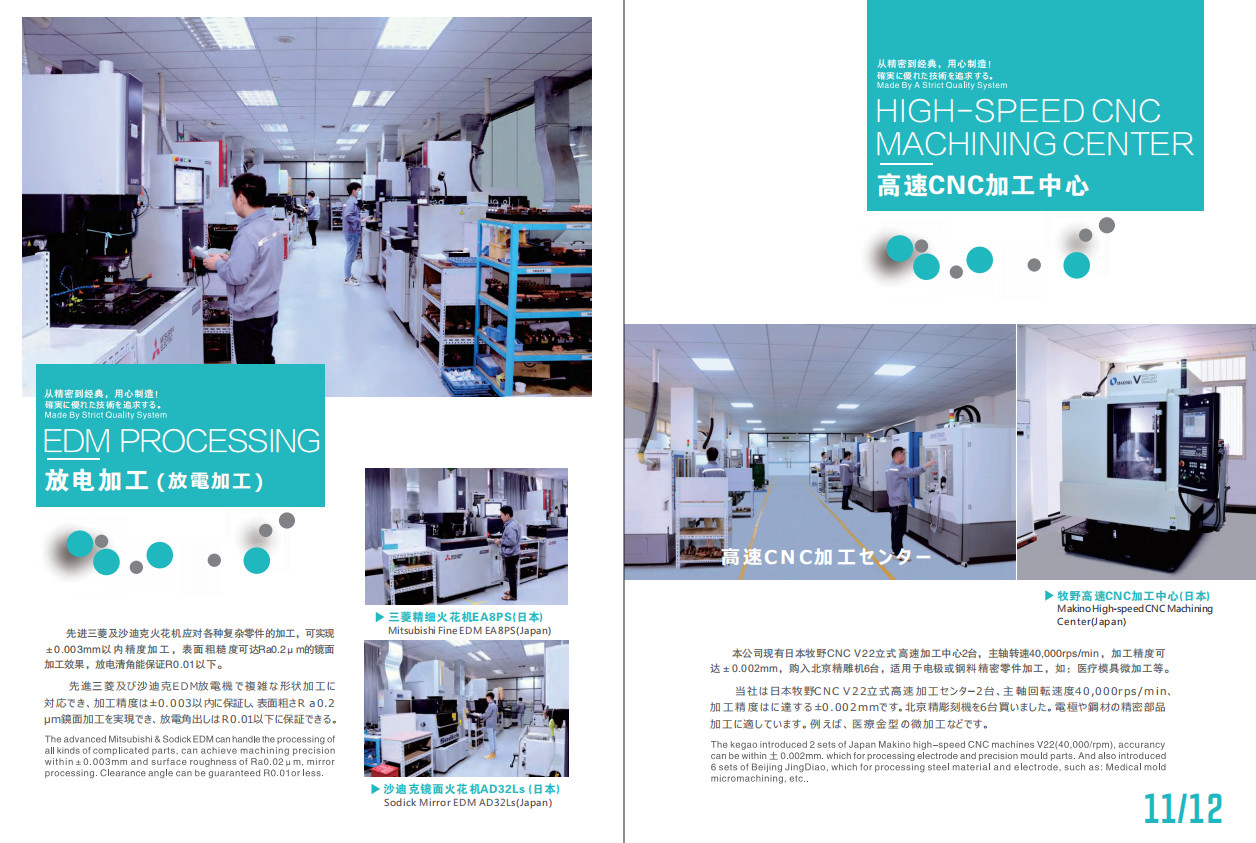

5. Machining: lath machining, cnc machining, wire cutting,

discharging processing, grinding processing, internal- external

lapping and so on.

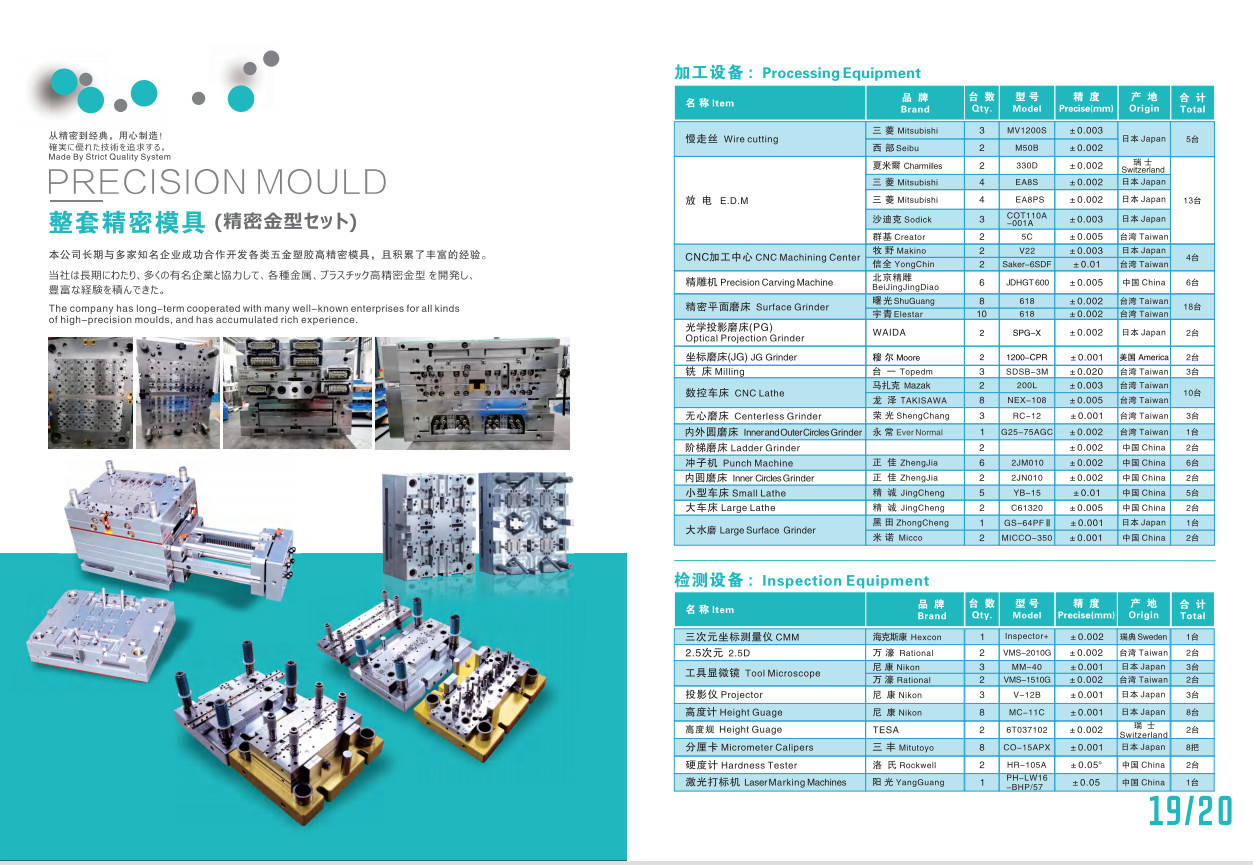

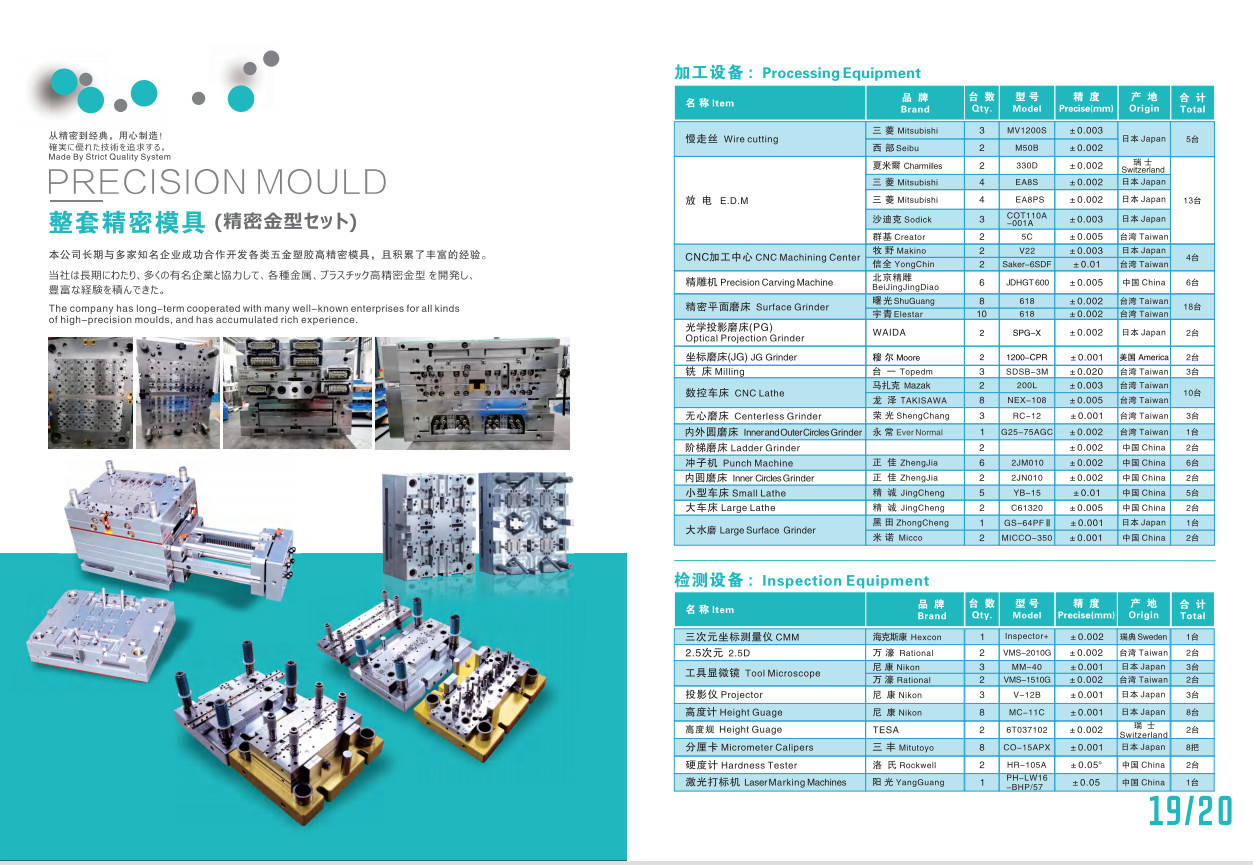

6. Our Euipements: CNC milling machine, CNC machine, grinder, EDM

machine, WEDM machine and so on.

7.Testing equipment: 2.5D projector, Japan Nikon Height Gages and

others, two dimension, hardness meter and so on.

8. Tolerance: 0.005mm

If you have some questions about plastic moulds, or want to know

more about auto mould parts, medical mould parts, packaging mould

parts, cosmetic mould parts, connector mould parts etc. Welcome to

contact us!